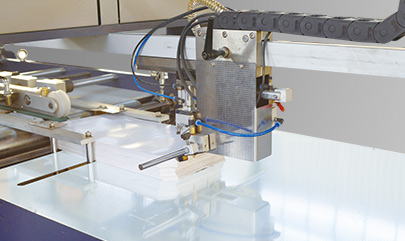

The feeder in this machine adopts back-suck&push feeding system, which is pneumatic structure and can avoid feeding of two pieces paper.

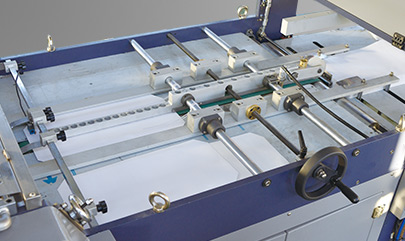

Easy operation and no scratching in folding unit, belts combined with mechanical edge-repairing structure can reduce surface friction effectively.

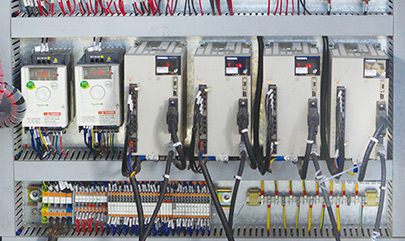

Human-machine interface, PLC and servo control system make operation easy to achieve accurate action and high speed.

Automatic paper registration and ultrasonic detecting devices can detect the double pieces paper effectively.

Adopts imported high-precise photoelectric control device from Germany to make the cardboard located more accurate (±0.2mm). Negative pressure detecting function makes machine alarm if there is not cardboard feeding, avoiding paper waste.

High technology, auto paste inside lined paper and iron sheet.(Optional)

Human-machine interface operation, touch screen control

冀公网安备13022902000399号

冀公网安备13022902000399号